(Ⅷ)Special Equipment Safety

Special Equipment Safety

(Ⅰ) Pressure Equipment

1. Check pressure equipment on a regular basis to ensure that it is safe. For pressure vessels that have been idle for a long-time, they

have to pass the inspection conducted by special equip- ment department before use.

Special Equipment Safety

(Ⅰ) Pressure Equipment

2. Personnel operating pressure equipment have to receive training offered by relevant departments and be certified. Operate according to the established operating guidelines.

3. When operating, the operator should not leave the site.

Special Equipment Safety

(Ⅰ) Pressure Equipment

4. Stop operating once there is abnormality. Inform the person charging the equipment.

Special Equipment Safety

(Ⅱ) Lifting Equipment

1. Check lifting equipment on a regular basis to ensure its safety.

Special Equipment Safety

(Ⅱ) Lifting Equipment

2. Personnel operating lifting equipment have to receive training offered by relevant departments and be certified. Operate according to established operating guidelines.

3. Check the equipment thoroughly and carefully before using.

Special Equipment Safety

(Ⅱ) Lifting Equipment

4. Lifting equipment must not lift objects exceed- ing the allowed limitation.

(二) 起重机械

5.Any people should not stay within the range of the crane.。

Special Equipment Safety

Special Equipment Safety

(Ⅲ) Gas Cylinder

1.In principle, gas used in the lab should be purchased from an appointed su- pplier qualified through a bidding process held by university. For details, go to the website of the Department of Laboratory and Equipment Management.

Special Equipment Safety

(Ⅲ) Gas Cylinder

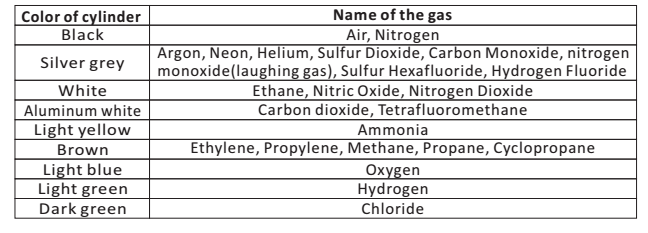

2.The department using gas should reject gas cylinders without appropriate label of the gas name, safety cap or bump protection ring, color signs and labels that certify its safety. Inform corresponding department and the De- partment of Laboratory and Equipment Management soon.

Special Equipment Safety

(Ⅲ) Gas Cylinder

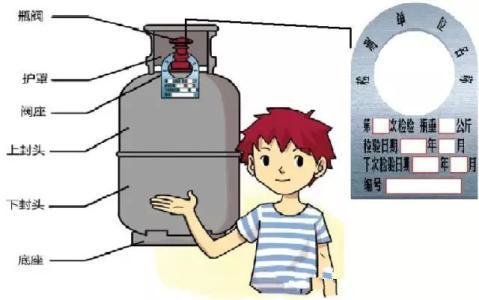

3.The department using gas should check information like the technical insp- ection tag, steel seal and other labels. Do not change the gas cylinder's st- eel seal and color-coded tag.

(Ⅲ) Gas Cylinder

4. Do not pile flammable, explosive or corr-

osive substances near the gas cylinders. Keep them away from heat source. Keep the environment well ventilated and dry. Avoid direct sunlight or strong striking. Categorize gases before storage. Do not have mix storage (flammable gas and co- mbustion-supporting gas). Do not store them in the hallway or public places. Ro- om or cabinet to store gas cylinders only should be locked and managed by a specific person.

Special Equipment Safety

Special Equipment Safety

(Ⅲ) Gas Cylinder

5. Gas cylinders should be properly fixed and secured from falling. Label the gas cylinder and the gas pipes. Hang signs to indicate the status of gas cylinders.

6.Choose appropriate pipes to deliver gas. Use metal pipe for flammable, explosive, poisonous gas. Do not use copper pipe for ethane, ammonia or hydrogen.

Special Equipment Safety

(Ⅲ) Gas Cylinder

7. Install bump protection ring for unfixed gas cylinders. Screw the safety cap tightly. Do not move while holding the main valve. Do not drag, roll or slide the gas cylinder.

Special Equipment Safety

(Ⅲ) Gas Cylinder

8.Categorize the pressure reducer for the gas. Check for leakage after installation. Be cautious about leakage. Be aware of the pressure gauge reading to avoid leakage or over-pressurization.

Special Equipment Safety

(Ⅲ) Gas Cylinder

9. When turning on the gas cylinder, switch the main valve before turning on pressure reducer. Once after using, turn off the main valve and release all the remaining gas. Then turn off the pressure reducer. Slowly turn on and off the pressure reducer, main valve and stop valve to avoid generating static electricity.

Special Equipment Safety

(Ⅲ) Gas Cylinder

10.If leaking, shut the gas source value, open windows and evacuate people around. Do not turn on or off electrical power during the leakage of flamm- able or explosive gas.

(Ⅲ) Gas Cylinder

11. Do not use up the gas in the cylinder. Retain some residue pressure.

12.In cases where reflux might take place, install equipment like one-way va- lve, nonreturn valve and buffer tank connecting the system pipes or equi- pment to prevent reflux.